Coal briquette equipment manufacturer

FUYU Machinery Co., Ltd. is located between Zhengzhou(the provincial capital of Henan) and Luoyang, which is an ancient national capital for hundreds years. The strategic location, convenient transportation and pleasant scenery provide an ideal environment for both domestic and foreign businessmen to discover the most suitable products.

Coal briquette line

Efficiently convert pulverized coal into briquettes to ensure production needs through crushing, mixing and pressing

Roller briquette machine

Used to compress powdery substances into solid coal blocks of different shapes. Wide range of applications

Charcoal extruder machine

Equipment that compresses biomass materials such as wood chips and sawdust into high-density rods.

Wood pellet machine

A device that converts wood waste such as sawdust into high-density combustible pellets.

Crushing machine

A shredder is a powerful piece of equipment that can break large objects into smaller pieces, making them easier to process and handle

Mixing machine

It can evenly mix coal powder and binder to ensure the best molding quality. Its design is rugged to withstand abrasive materials

Drying machine

It removes moisture from coal dust and improves coal quality and combustion efficiency.

coal bagging machine

It efficiently packs briquettes with minimal human intervention, ensuring consistent size and weight. It can adapt to different briquette sizes

charcoal bagging machine

The semi-automatic packaging machine in the briquette production line is the main force. It ensures that the briquettes are packed evenly and maintain consistency in size and weight. It can handle different sizes of briquettes

Automatic coal packing line

The fully automatic packaging machine in briquette production is a miracle. It automatically packs briquettes, ensuring uniformity and precision. It has strong ability to adapt to different briquette sizes

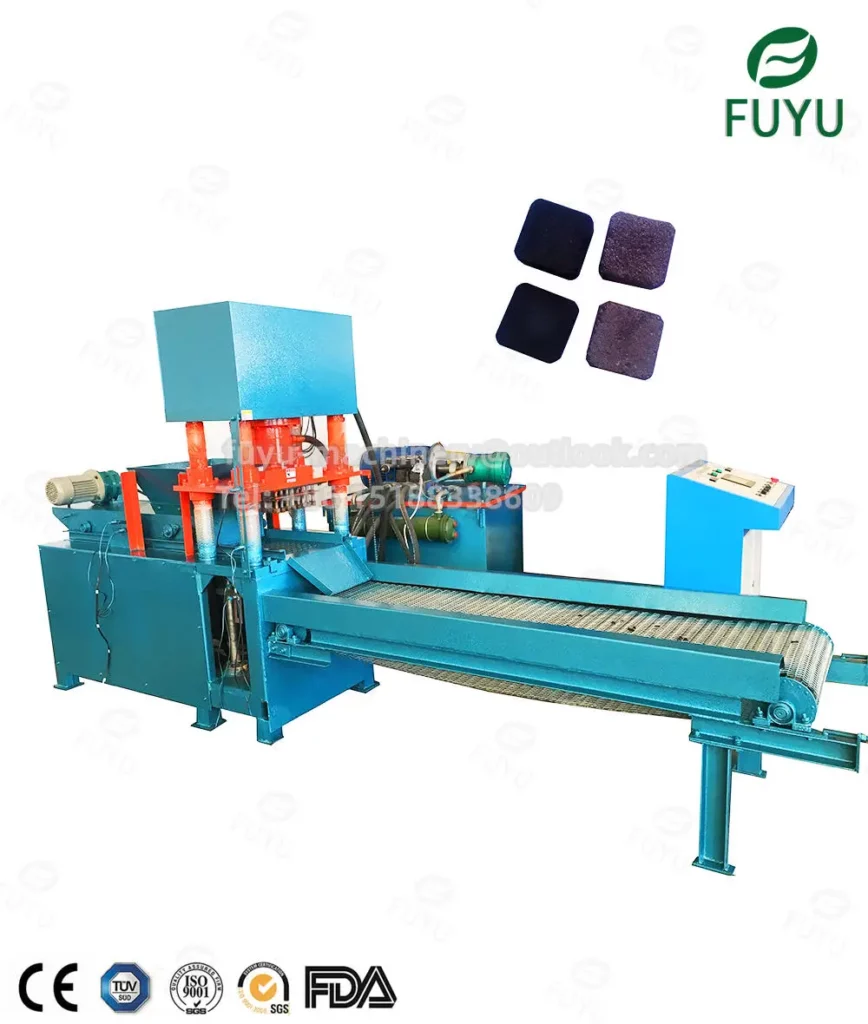

Shisha charcoal briquette machine

It converts pulverized coal into uniformly sized briquettes, thereby improving its combustion efficiency. Its high productivity and robustness underline its key role in production lines.

Advantage 1

Our company stands out in the industry for consistently delivering innovative and customized solutions that meet our customers’ unique needs, ensuring customer success and satisfaction.

Advantage 2

We take pride in our exceptional customer service, which is backed by our deep industry knowledge and expertise, enabling us to provide insightful and effective solutions to our clients.

Advantage 3

Our team’s unwavering dedication and diverse skill set are our greatest strengths, allowing us to deliver high-quality results that exceed our clients’ expectations.

Advantage 4

Our commitment to sustainability and ethical business practices sets us apart, as we strive to make a positive impact on society while providing top-tier services to our clients.

© 2024 All Rights Reserved.